See How We Delivered 22% Faster Cycle Times for Global Manufacturers.

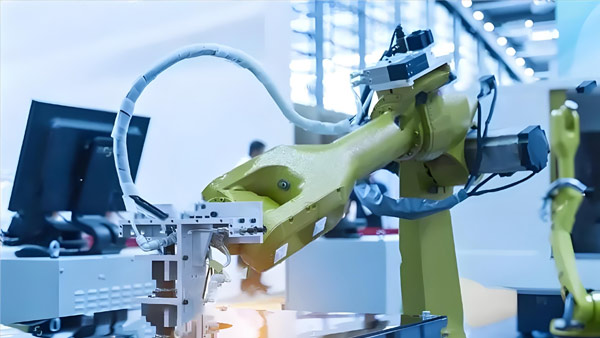

A global leader in industrial automation equipment selected GUANDN to engineer 13 advanced industrial tunnel oven systems for high-volume process industrial penetration membrane curing applications. The 50-day turnkey project demonstrated GUANDN's expertise in delivering scalable, energy-efficient solutions that address critical challenges in thermal uniformity and rapid production cycles.

Each custom industrial conveyor oven line incorporated GUANDN's proprietary Double-deck tunnel furnace design, featuring independent zone control and patented airflow optimization. This configuration achieved ±1°C temperature accuracy across 2.8m-wide chambers while doubling production capacity compared to single-layer systems. Energy recovery modules reduced operational costs by 35%, aligning with the client's sustainability goals.

The automation solution included IoT-enabled remote monitoring, automated material tracking, and predictive maintenance alerts, ensuring 99.8% uptime. GUANDN's modular design allowed for future expansion, with the systems complying with NFPA 86 safety standards and ATEX Zone 2 certification for hazardous environments.

This partnership highlights GUANDN's innovation in industrial tunnel oven technology, combining precision thermal engineering with smart automation to meet the demanding requirements of medical device manufacturing. The project achieved full production ramp-up in 42 days, validating GUANDN's position as a trusted provider of high-performance industrial automation equipment.

Share your specs—we’ll design, optimize, and deliver.

Address:No. 998, Juting Road, Zhuangxing Town, Fengxian District, Shanghai, China

Email:support@gdoven.com

Phone:+86 19921692198

WhatsApp:+86 19921692198

Share your specs—we’ll design, optimize, and deliver.

Address:No. 998, Juting Road, Zhuangxing Town, Fengxian District, Shanghai, China

Email:support@gdoven.com

Phone:+86 19921692198

WhatsApp:+86 19921692198